Hangzhou Datian CNC Machine Tool Co., Ltd. was established in 2005. The founder is the former director of Hangzhou Combined Machine Tool Research Institute. He has more than 50 years of experience in machine tool design, R&D and production. It has total assets of more than 150 million yuan, net assets of 80 million yuan, a construction area of 22,000 square meters, and more than 200 employees. It is a national high-tech enterprise, an enterprise undertaken by the National Torch Plan, an enterprise undertaken by the National Innovation Fund, an innovative enterprise in Zhejiang Province, and a patent demonstration enterprise in Zhejiang Province.

The Gold Award Enterprise with the Most Development Potential in Hangzhou, and the 2017 Top Ten Innovative Achievement Award-Winning Enterprises of Civil-Military Integration. Product Introduction

Product Introduction

Under with internationally renowned companies such as Germany Bosch Electric, France Vesuvius, and Japan Yamaha for many years to develop high-end CNC compound machine tools; and creatively combines the internationally popular FCM CNC compound machine tool technology with FMS Flexible manufacturing technology integration, research and development to form the following products; "Five-sided composite flexible manufacturing unit", "three-sided composite windlass gearbox flexible manufacturing unit" and GAB vertical, horizontal and gantry composite manufacturing centers with more than 80 independent intellectual property rights in China : Fill the gap of flexible processing of large-scale key parts in China, and reduce the blockade of large-scale high-end machine tools and intelligent production lines in my country by western countries; Domestic high-speed and high-precision GQ small gantry, with portal rigid structure, strong base, optional high-speed spindle, High-precision spindle, high-rigidity spindle; optional main functional components such as German-Japanese and domestic systems, screw rods, linear guides, etc., suitable for high-speed cutting, high-precision machining and heavy-duty machining, it is an ideal equipment to replace imported vertical machining centers.

Creavitity

Creavitity

Under the guidance of the former chairman of China Machine Tool Association Liang Xunxuan: the company has cooperated with internationally renowned companies such as Germany Bosch Electric, France Vesuvius, and Japan Yamaha for many years to develop high-end CNC compound machine tools; and creatively combines the internationally popular FCM CNC compound machine tool technology with FMS Flexible manufacturing technology integration, research and development to form the following products; "Five-sided composite flexible manufacturing unit", "three-sided composite windlass gearbox flexible manufacturing unit" and GAB vertical, horizontal and gantry composite manufacturing centers with more than 80 independent intellectual property rights in China : Fill the gap of flexible processing of large-scale key parts in China, and reduce the blockade of large-scale high-end machine tools and intelligent production lines in my country by western countries; Domestic high-speed and high-precision GQ small gantry, with portal rigid structure, strong base, optional high-speed spindle, High-precision spindle, high-rigidity spindle; optional main functional components such as German-Japanese and domestic systems, screw rods, linear guides, etc., suitable for high-speed cutting, high-precision machining and heavy-duty machining, it is an ideal equipment to replace imported vertical machining centers.

Personalized customization and service-oriented manufacturing

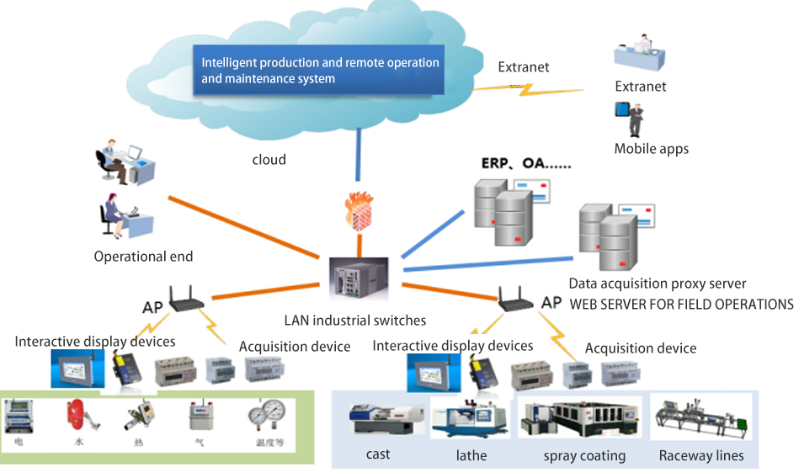

The company is committed to R&D and production of various vertical, horizontal, gantry and composite machine tools to replace imported equipment, and to provide users with customized high-end CNC machine tools. The development concept is to provide users with machine tool hardware, software and services; to provide intelligent machine tools, embedded Software, centralized information management and remote operation and maintenance services, narrow the software technology gap with imported machine tools.

MD heavy cutting and efficient...

MD heavy cutting and efficient...  VHRW 500 vertiacl and horizont...

VHRW 500 vertiacl and horizont...  GQ800 Powerful Small Gantry Ma...

GQ800 Powerful Small Gantry Ma...  HH series moving table double ...

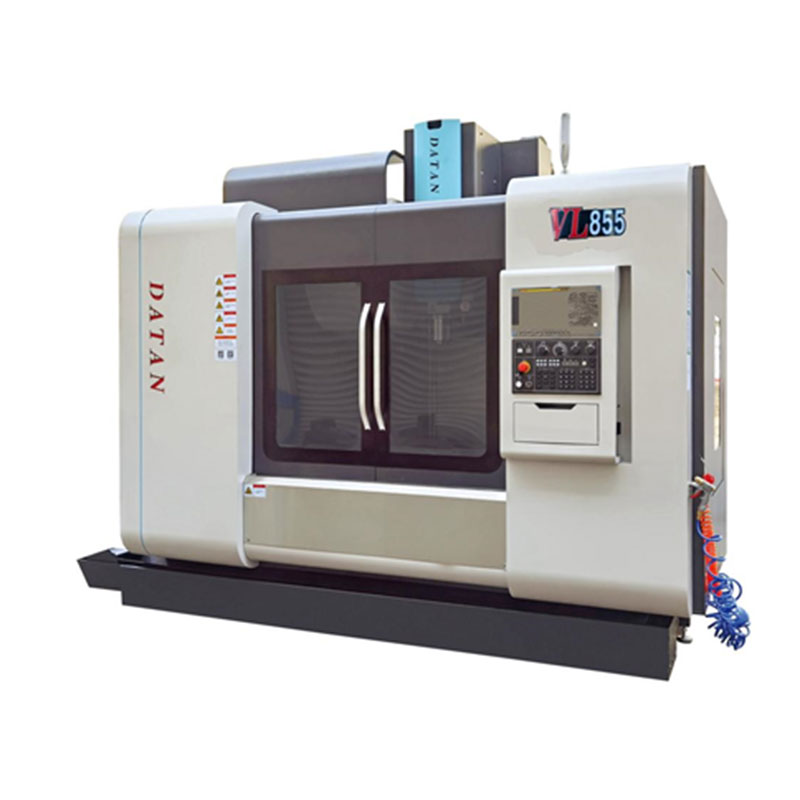

HH series moving table double ...  VL high precision vertical mac...

VL high precision vertical mac...  MD/DF heavy cutting and effici...

MD/DF heavy cutting and effici...  ME series vertical machining c...

ME series vertical machining c...  VM series moving column machin...

VM series moving column machin...  GQ Powerful Small Gantry Machi...

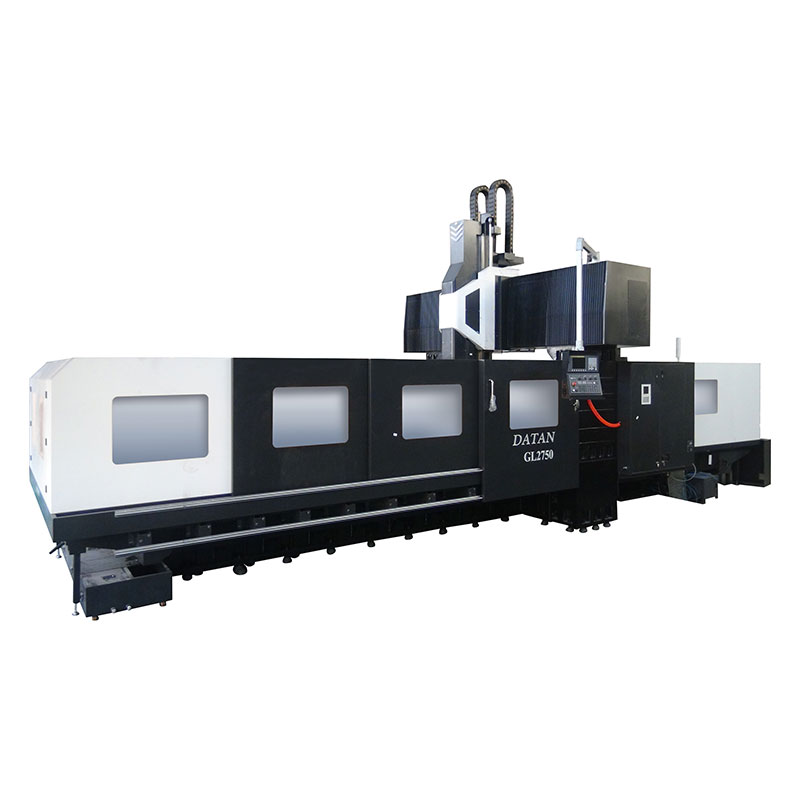

GQ Powerful Small Gantry Machi...  GL medium-sized gantry machini...

GL medium-sized gantry machini...  HH series moving table double ...

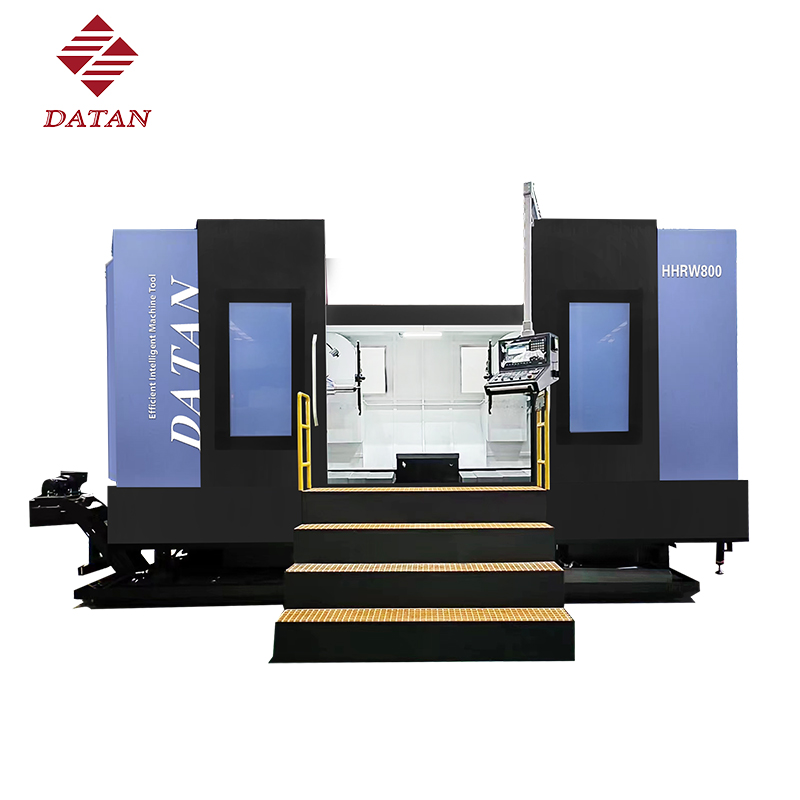

HH series moving table double ...  HHRW series moving column doub...

HHRW series moving column doub...  GHRW fiveside compound machine

GHRW fiveside compound machine  HL series horizontal machining...

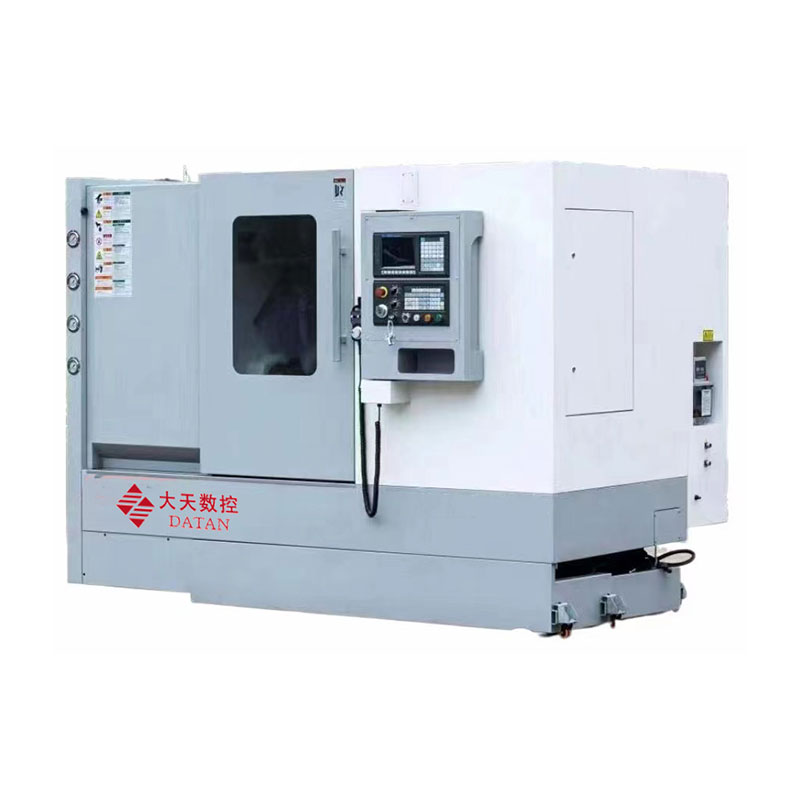

HL series horizontal machining...  SCK series

SCK series  CK series

CK series