Comparison of 3-Axis and 4-Axis CNC Machining Centers

Date: 2020-10-20 Categories: Industry News Hits: 823

When choosing between 3-axis and 4-axis CNC machining centers, it’s important to focus on the suitability of each machine for specific tasks rather than which is better overall. Both machines can handle many of the same operations, but a 4-axis machining center has advantages in handling more complex geometries that a 3-axis machine cannot. The key difference lies in the addition of a rotary axis (the fourth axis) in 4-axis machining centers, which is achieved using a dividing head. This accessory, controlled by the CNC system, allows synchronized movement with other axes, enabling precise positioning and rotational machining. While 3-axis machines are limited to operating within the X, Y, and Z axes, 4-axis machines expand capabilities by allowing work on multiple faces of a workpiece without repositioning.

In terms of programming and operation, the differences between 3-axis and 4-axis systems are minimal, making it easy for operators familiar with 3-axis systems to adapt to 4-axis machines. However, the choice between the two should depend on the specific machining requirements. If a 3-axis machine can handle the work, it is typically more cost-effective, as 4-axis machines are generally more expensive. On the other hand, for projects involving complex parts and precision machining, a 4-axis machining center provides significant advantages.

MD heavy cutting and efficient...

MD heavy cutting and efficient...  VHRW 500 vertiacl and horizont...

VHRW 500 vertiacl and horizont...  GQ800 Powerful Small Gantry Ma...

GQ800 Powerful Small Gantry Ma...  HH series moving table double ...

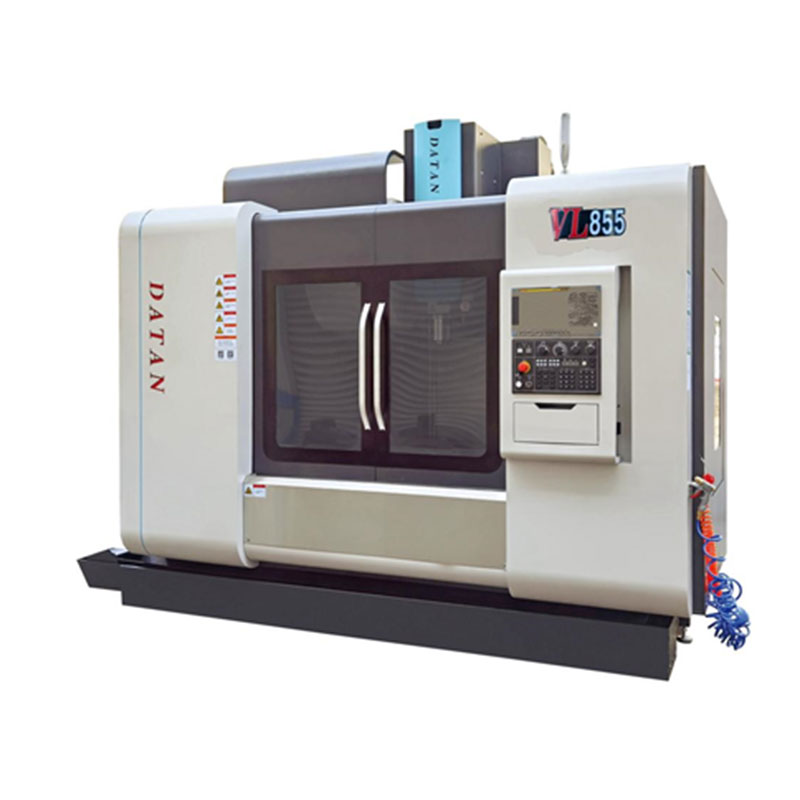

HH series moving table double ...  VL high precision vertical mac...

VL high precision vertical mac...  MD/DF heavy cutting and effici...

MD/DF heavy cutting and effici...  ME series vertical machining c...

ME series vertical machining c...  VM series moving column machin...

VM series moving column machin...  GQ Powerful Small Gantry Machi...

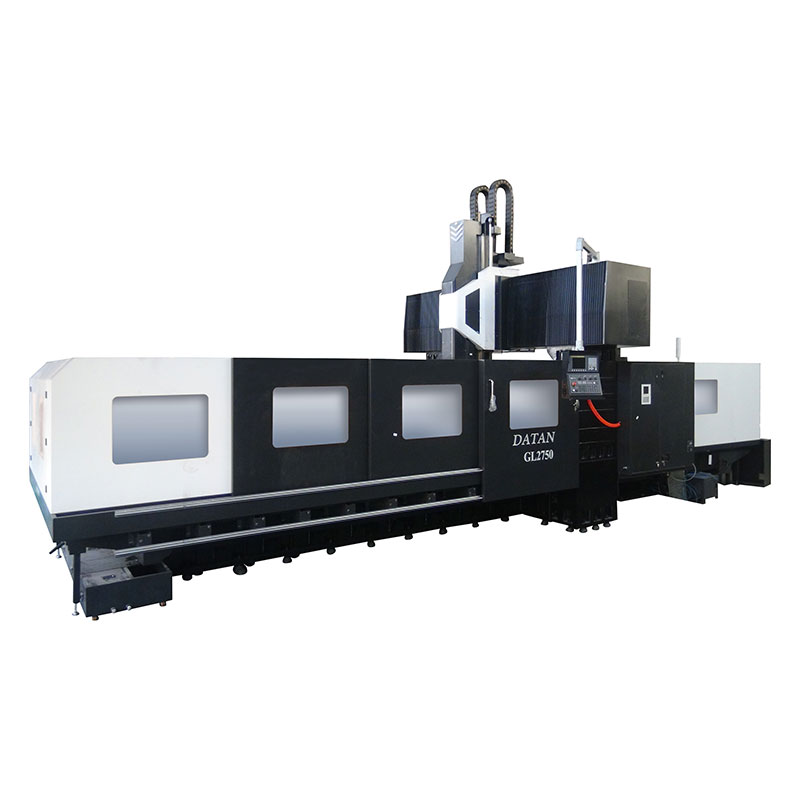

GQ Powerful Small Gantry Machi...  GL medium-sized gantry machini...

GL medium-sized gantry machini...  HH series moving table double ...

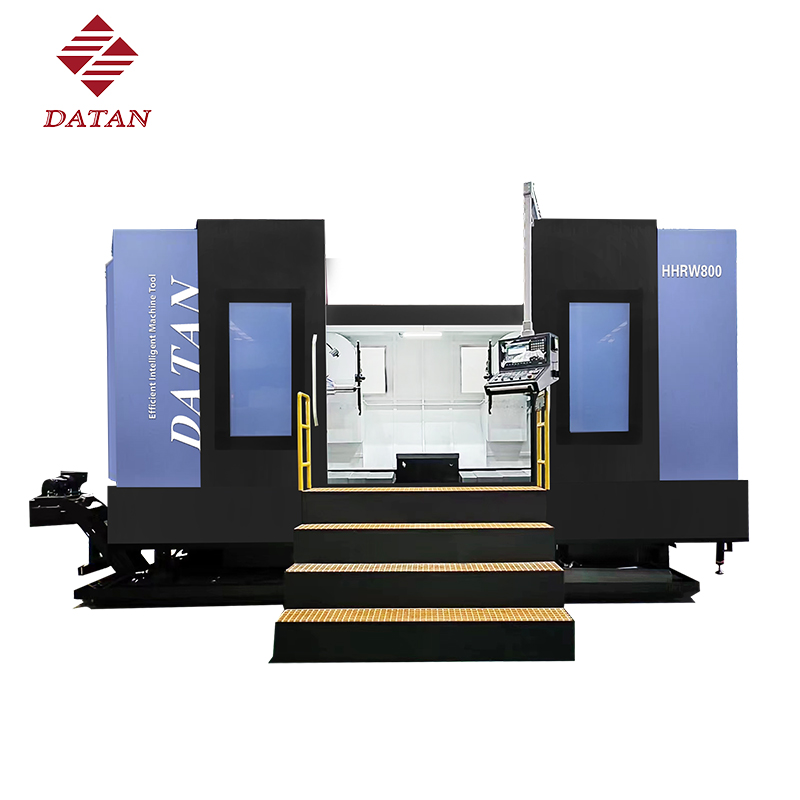

HH series moving table double ...  HHRW series moving column doub...

HHRW series moving column doub...  GHRW fiveside compound machine

GHRW fiveside compound machine  HL series horizontal machining...

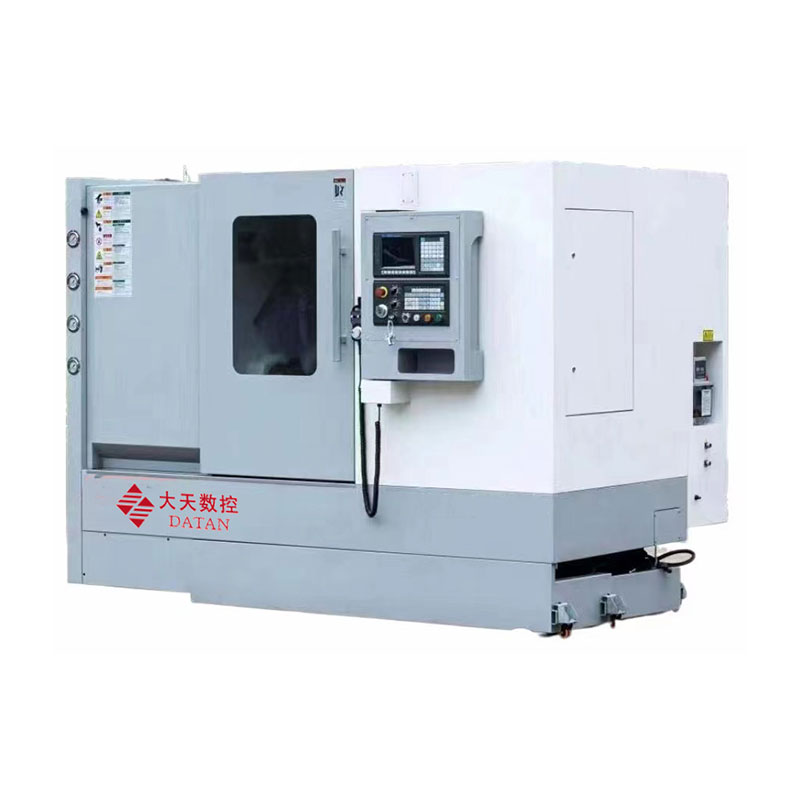

HL series horizontal machining...  SCK series

SCK series  CK series

CK series